Treating Machine

SpotTEC

product features:

|

·Simple installation and easy to use ·Easy maintenance ·Single or dual head configuration ·Gas flow control ·LDE can display operating conditions ·Strong processing flexibility |

|

Tantec's SpotTEC equipment is used to handle surfaces such as rubber seals, cables, and injection molded parts, and can be integrated on the production line, allowing users greater flexibility in use. The basic principle is that the ions of the high voltage discharge act on the surface of the object under atmospheric pressure, thereby improving the adhesion of the surface of the object.

Tantec's SpotTEC is mainly used to treat the surface of extruded plastic products such as three-dimensional molds or rubber seals to improve their surface adhesion. Using this equipment to treat the surface of objects can reduce the cost and achieve good benefits.

The basic working principle of SpotTEC is to perform high-voltage discharge in the high-frequency region. The electric ions near the two electrodes on the electrode head are driven by the air to the surface of the object to improve the surface characteristics of the object.

SpotTEC is easy to install on new or existing production lines and processes the product to better adhere glue, ink or paint to the surface of the object.

SpotTEC equipment is the best solution for treating various plastic products.

SpotTEC complies with CE and EMC regulations.

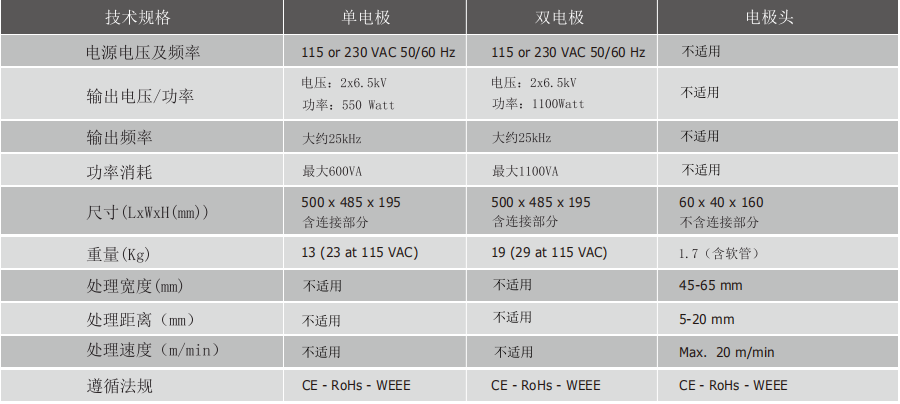

The device is available in single and double head types.

Features:

·Simple installation and easy use The device does not need to adjust the processing parameters, it only needs to be connected to a power source to run.

·Easy maintenance. Just change the metal electrode.

·Single or double-ended configuration One discharge generator is equipped with single or two electrode tips.

·Air flow control During processing, air flow can be detected to ensure proper air flow.

·Air flow control During processing, air flow can be detected to ensure proper air flow.

·Strong processing flexibility Handling non-conductive surfaces (up to 20m / min) at low speeds.