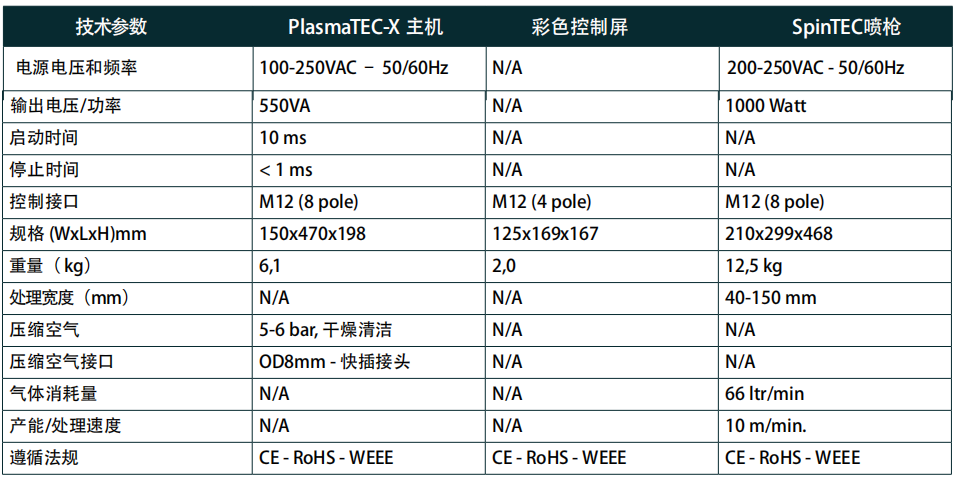

Treating Machine

SpinTEC

product features:

|

· Easy installation · Fast processing speed · control signal · Automatic airflow adjustment · Standby low airflow · Small size and light weight · Processing control output · PlasmaREMOTE |

|

Tantec and PlasmaTEC-X are new surface treatment equipments designed based on the principle of high-voltage DC plasma discharge at normal pressure. The device can be integrated into the robot system alone or on any production line.

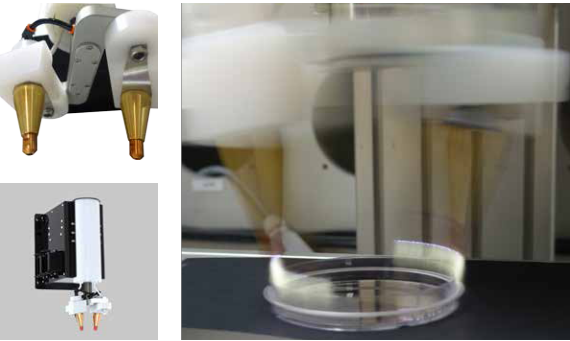

SpinTEC is an AC motor that combines two PlasmaTEC-X nozzles in the lightest way to form a high-speed rotation processing mechanism with the axis as the rotation point.

It is connected and controlled with the standard host computer and touch screen. The processing area can be adjusted from 40-150mm width. The rotating motor of the spray gun head can reach 2500rpm / min and the processing speed can reach 10m / min.

The AirTEC system can ensure that the air pressure of the spray gun is in a correct pressure value range. Real-time monitoring with the PlasmaTEC-X circuit system ensures the air pressure status during processing. The AirTEC system can automatically adjust the length of the gun line.

The AirTEC system and unified power input make PlasmaTEC-X easier and more convenient to use, without any adjustments, just connect the power supply and compressed air and use it.

Tantec's new energy-saving function is applied in the low-pressure standby state. Setting the "low-pressure standby state" through the touch screen operation can ensure and avoid excessive loss of air pressure during non-processing.

SpinTEC is easily connected to the host via a standard plug. The combination of mature DC control technology and AirTEC's air control technology enables the device to achieve the effect of rapid production without the need for tuning, fast installation, and without worrying about the impact of pipeline length on the device.

Features:

·Easy installation Just connect power and compressed air, no need to adjust air pressure and power.

·Fast processing speed In the state that the material can withstand, the high-power effect can reach a speed of 10 meters per minute.

·Potential-free plasma process for conductive, non-conductor and semiconductor product surfaces

·Output processing control If the output voltage is lower than its inherent state, the host will issue an alarm signal.

·Process monitoring Various signals can be displayed on the digital interface. The test is to control and monitor the processing effect of the plasma.

·Automatically adjust the air flow No matter how long the power cord or pipeline is, the host will automatically adjust to ensure the right amount of pressure and gas flow.

·Standby airflow The standby airflow mode can be opened or closed through the operation panel, while avoiding waste of air supply and the impact of dust on the spray gun.

·Small size and light weight This feature allows SpinTEC to be easily integrated into any production line or robot system

·Control status During the process, gas-assisted processing such as oxygen and argon can be added, but this needs to be considered.